Diversion of material may be required in industries where different outputs are prepared with same material.

At any point of time, in your process, you may require using raw material or processed material for two different processing.

In such cases, rather than using two completely different processes, you can divert the processes from where they should chance.

For example, in paper industry, you may require paper pulp for manufacturing two different types of papers but the pulp remains same. Hence, the process of producing pulp remains same and you can use the diversion method to send the pulp to two different lines from one place.

However, you may control the flow of material with a good diverter valve.

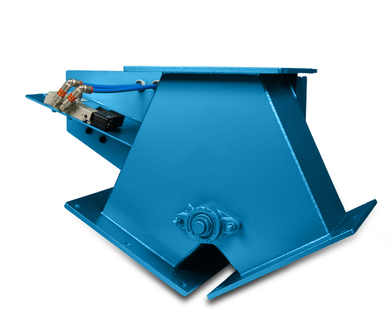

Diversion of material can be simple if your material works with gravity. You only need to rotate the covers to open and close the diversion points and material will flow.

This simple technology saves a lot of cost and efforts. Material keeps moving with gravity flow and rotation of flaps help in managing the material inflow in two different processes.

You need no pressure for such diverter valve.

The whole process if filled with material and it keeps moving with gravity force while directed by the flaps. You can increase the diverter points. Instead of two, there can be three points of diversion from where three different diversions may take place.

Sometimes, the further process is tough and capacity of one machine may be lower. In that case, also, you can divert the load to different machines and increase your overall capacity.

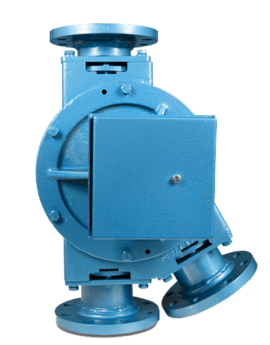

While simple diverter valve works with gravity application, there are some industries where pressure is required. Valves that work under air pressure are also available for a better diversion of high-pressure material processes.

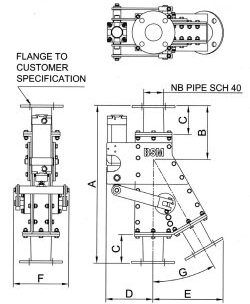

Pneumatic diverter valve have two sections. Considering there is a high flow, the diversion may affect hence, there is a flap for inlet of material from main pint and another flap for diversion. The cone structure allows good pressure even with two flaps so material movement remains easy.

Whether it is simple or pneumatic diverter valve, the internal surface of valves remains smooth to avoid any residual inside. It also enhances cleanliness. While the overall body is a mixture of cast iron, cast aluminum and stainless steel, flaps are made of stainless steel only.

The seals are made of food safe rubber hence making the whole process food safe. The operation can be hand handled, electric or pneumatic as per your requirement.

Whether you use for gravity application or on a conveyor line, diversion of material needs a little technique but it serves a huge purpose.

You need very less power to operate this and the valve fits well in your process line making it run smooth.

While he functioning is smooth and easy, quality of equipment is also good. Any little fault in your conveyor line disturbs the whole process and shows you down time.

Sunco Powder Systems, ensures quality equipment that makes your work easy and cost effective.