In heavy manufacturing units, taking care of every small bits of parameters are pretty important. Rotary valves are very popular in market and have been in practice since long time. For those conveyor belts where tough materials are being prepared, these valves are inevitable. In case of vehicle automation, these valves are pretty popular.

Now you know why people are in love with these valves at the first place! In case of pneumatic production chain, this is certainly the best mechanical element available in the production industry.

Talk to the experts from Suncopowder and they will also say this to you! There are lots of companies are available that sell these products, find the best one among them and buy that product for your convenience.

Placement of valves are very important

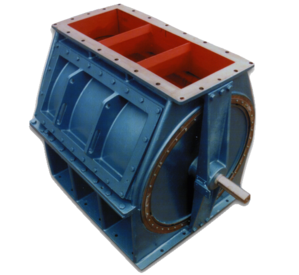

These valves are placed at different level on the production line as per the requirement of the owner. The valve has an inlet and of course an outlet. There are two flanges available within the valve body.

These flanges are placed like two gears and they rotate simultaneously making the whole system work properly. Generally these valves are made with cast iron or carbon steel. In case of heavy duty mechanisms they are used generally and used in plenty.

In case of engines and mechanical machines or apparatus manufacturing units also have such valves everywhere in the production chain. The outer layer of the valve is protected with a proper coating of either fabricated material, sheet or casting.

Depending on the place where the valve is placed, the outer layer is given. Consultants are available everywhere, but at suncopowder they actually spare time for you and discuss the whole design with you.

Working mechanism

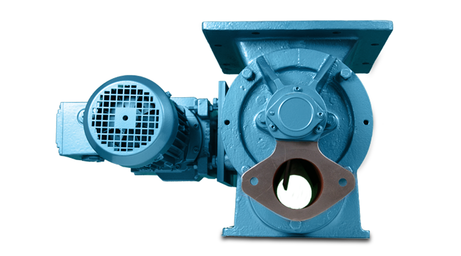

Sanitary Rotary Valve

The working mechanism of rotary valves are amazing and alluring. These valves are pretty tough to handle. They are placed on the system chain and are made of tough sturdy materials giving no space for materials to move or escape.

The sealing is pretty tough. In case of those production chains where powdery products are made, the heavy chance of product loss persists. But the sealing is tough in this case.

Talk to the experts from Suncopowder to understand this mechanism in details. If heavy materials are made in the production house, abrasion takes place. The tough sealing of rotary valves make sure that the abrasion level is minimized and keep under control.

Pressure should be maintained

If the pressure within the production chain goes off the limit, a chance of sand blasting takes place. It is important to make sure that the pressure is kept within the limit. In case of those production chain where the powdery products are made, it is important to create an air free zone or air locked zone.

There should be no air flow from the inlet to outlet. Else, the powdery product may flow from a place to another diminishing the production quantity. This is the reason, rotary valves are very important in case of production companies. No matter how simple or complex the conveyor belt design is, rotary valves can be placed at any point!

Cost effective

With the accurate use of rotary valves, the production cost can be cut to good limit. When a company runs a production chain, the optimal target of the company is to limit the price and increase the production every day.

Rotary valves can help maintaining the pressure, increasing the power and efficiency of the manufacturing unit. Reach suncopowder on time and get your job done.