Many residential and commercial areas require the incorporation of valves to maintain the flow of fluid, handle the accumulation of dry solids and slurries. To meet the expectations of smooth fluid flow, industrial areas employ the use of knife gate valves and diverter valves.

In this following article, you will get an in-depth insight into the two valves and how they fit the industrial needs.

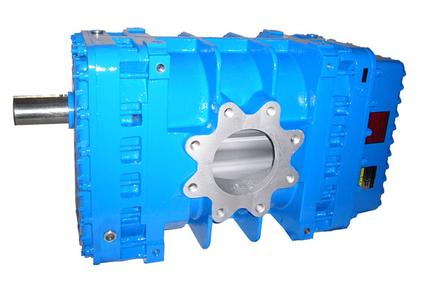

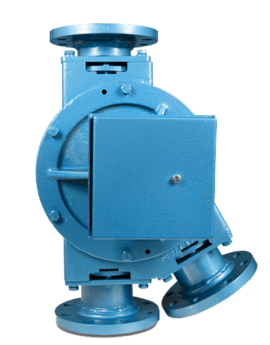

A gate valve, also popularly known as a sluice valve, refers to a system that opens up with lifting of the gate. The feature gives easy access to the fluid flow. Gate valves serve many purposes, the most important being the free flow of the fluid.

Knife gate valves offer isolation services in areas with a high concentration of suspended solids.

The general purpose of the knife gate valve:

The widespread use of the Knife gate valve is to cut through the regions of pulp and seal with the help of a sharp edge.

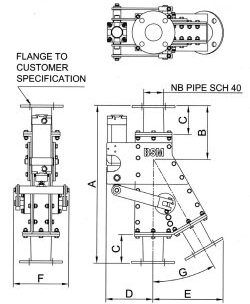

Structure:

The gate of a gate valve is usually parallel, but at times there are wedge-shaped tools to allow proper flow regulation. The negligible resistance to the flow of liquid is noteworthy in terms of its application.

Distinct Features:

• The heavy-duty knife gate valves fit the purpose to cut through solid sediments.

• The gate area has surface coatings like Hard facing, Nit riding, and Chrome-plating to meet varied goals.

• It has easy maintenance and replaceable seats. In addition to that, it operates in low torque to enhance the service life of these knife gate valves.

• Pressure ratings of PN10 and Class 150.

• Body materials like ductile iron, carbon steel, cast iron, and stainless steel with attributes like a long neck and an extended stem serve different purposes.

Areas of application:

- Larger pipes of larger diameters.

- Areas of minor leaking like heating circuits and sewer pipes.

- The knife gate valves handle slurry, corrosive, viscous, and abrasive media.

- Offer wastewater applications to overcome corrosion.

- Knife gate valves find applications in the entirely open or closed position.

- It provides reliable shut-off in case of dry and wet line fluids.

- Minerals and metals, paper and pulp, thermal power plants, steel plants, and chemical industries.

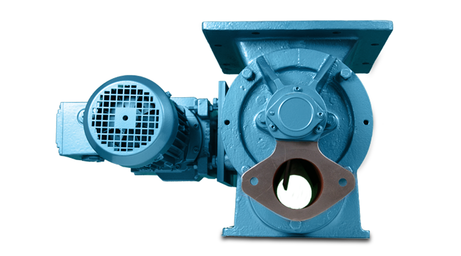

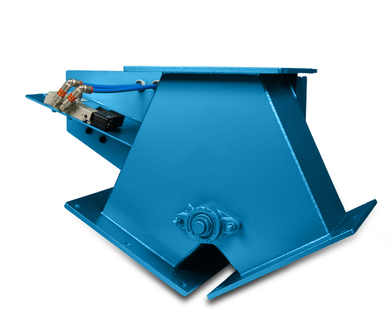

A diverter valve is a valve that diverts the direction of flow of the fluid. The easy to use plumping hardware makes it suitable for showerheads to redirect the flow of water.

The general purpose of the knife gate valve:

The public purpose served by diverter valves is to switch the direction of the flow of water between the shower head and the tub faucet. Thus, the mechanism helps to eliminate material cross-contamination.

Structure:

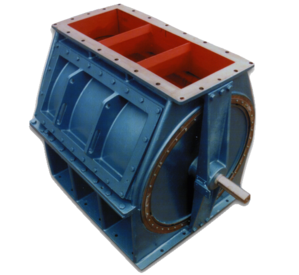

A diverter valve contains a hinged disc to close one outlet. They alter the flow stream with the help of pneumatic pressure mechanism. Close tolerance handles the entire structure. The outlets work in a fashion to master the movements of custom made sealing pad and sensors. Besides, there is an internal “swan neck” that rotates about the selected position. There is a jacking system to monitor the regulation of the swan neck and outlet.

Distinct Features:

- The valve is located between the two-tap faucet and the taps. In addition to this, there is a third faucet to divert the water flow direction through the valve.

- Some systems utilise L-shaped valves where a single dial adjusts the water temperature. In this case, the valve handles the direction of water flow.

- A straight handle pulls up the water towards the showerhead.

Areas of application:

- Diverter valves find use in flow control and pipelines since they work in conjunction with several other valves.

- Commercial areas like agriculture and farming, chemical manufacturing, aviation and aerospace, food processing, to name a few.

Final verdict:

From the above concept, it is clear about how a knife gate valve and diverter valve find a distinct yet comprehensive range of applications in different fields. Besides, it’s quite evident that diverter valves cover a wider area for commercial purpose to prevent flow shut-off.