In 2019, there has been a very pointed focus on a lot of different industries across the US, and with this has come about a particular focus on heavy bulk material handling operations for different types of industries. What this means is that companies that usually deal in handling, sorting and packaging heavy bulk material have now amped up their operation by several times, and as a direct result, a new need for different types of bulk material handling equipment, like blower packages has been created all over the US, in more than hundreds of different, unique clients.

In fact, a lot of products and recent innovations, such as gardner denver, were previously only niche machines used by very select companies for a small number of operations have now gotten the opportunity to come to the spotlight, and have revealed themselves as useful machines that just about every company wanting to optimize their operations should purchase, if only for the massive convenience they offer to their users! As one might imagine, this has definitely led to lots of bulk material handling companies to come to the very forefront of the industry, and to be able to show their true quality of product and marketing skills to the world.

Marketing Truths: A Huge Requirement in the Industry

There are lots of things that a company has to offer to their clients in order to build up a reliable and steady customer base, and one of the very basic facts in marketing is that any company must offer a list of advantages and benefits that they provide to their customers, or their products have over other, similar products made by their competitors. Otherwise, clients will have no reason to pick this particular company over their competitors, making marketing a fairly important trait in heavy bulk material handling equipment manufacturers.

However, no matter how good a company’s marketing skills are, the facts they state must be truths, or the marketing can actually harm a company much, much more than it can benefit them. The reason for this is fairly obvious, as no customers will want to buy products from a company that is known to lie about the qualities of their products, or to state false features and advantages that their products have over other products made by other companies.

Buying Products from suncopowder.com

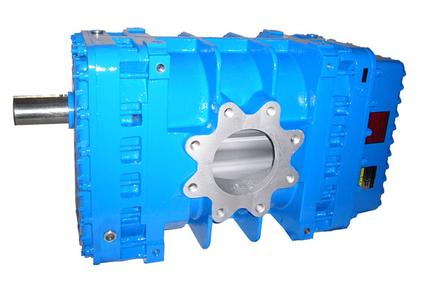

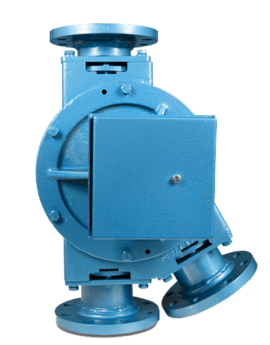

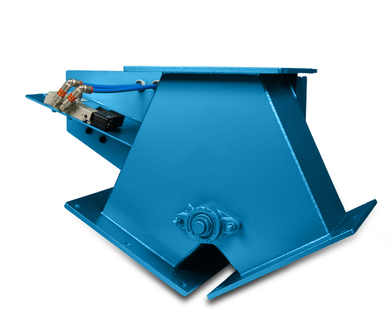

Over the past few years, many companies have been known as good manufacturers of bulk material handling equipment, but none have become as famous as SunCo Powder Systems, a company that has surprisingly become famous all over the US! While their fame comes about as a surprise to most newcomers, it’s fairly obvious to veterans of the industry, along with the massive amount of return customers they get, since the company is known throughout the USA to be a company that only manufactures the best have bulk material handling equipment like sutorbilt and diverter valve.